Dieselsite TurboMaster Wastegate Controller for Ford (1998.5-07) 5.9L Cummins (Style #1)

TM24

Dieselsite TurboMaster Wastegate Controller for Ford 5.9L Cummins (Style #1)

It is no secret that the factory boost control system on the 24V is a poor design. The factory control is a spring-loaded canister. The PCM sends a small amount of boost to the canister to override spring pressure and allow the wastegate to open. The downside is the wastegate opens and closes often prior to "set point" simply because of it's design. Aftermarket "actuators" simply are higher tension spring. You could accomplish this simple task by shortening the wastegate rod. It delays the "set point", but doesn't overcome the issue of the wastegate's lack of staying shut until desired. The Turbo-Master waste gate controller is created as a direct, bolt on replacement for the factory spring loaded canister. In combination with the factory waste gate valve, the Turbo-Master forms a fully adjustable, turbine inlet-pressure (drive pressure) relief system. With the Turbo-Master, turbine inlet pressure is retained up to the preset point of bypass. This results in turbocharger performance that is increased across the design operational range. Even on an otherwise stock Cummins engine performance is increased by virtue of the resultant steady boost pressure.

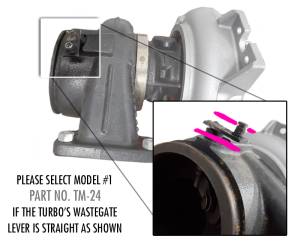

To ensure the correct Turbo-Master is selected for your application, please confirm your turbocharger's wastegate design using the pictures below. Many customers have turbochargers installed on their trucks that may be different from the model that typically came with the truck from the factory. The year model truck you have does not always correspond with a specific turbocharger model.

It is no secret that the factory boost control system on the 24V is a poor design. The factory control is a spring-loaded canister. The PCM sends a small amount of boost to the canister to override spring pressure and allow the wastegate to open. The downside is the wastegate opens and closes often prior to "set point" simply because of it's design. Aftermarket "actuators" simply are higher tension spring. You could accomplish this simple task by shortening the wastegate rod. It delays the "set point", but doesn't overcome the issue of the wastegate's lack of staying shut until desired. The Turbo-Master waste gate controller is created as a direct, bolt on replacement for the factory spring loaded canister. In combination with the factory waste gate valve, the Turbo-Master forms a fully adjustable, turbine inlet-pressure (drive pressure) relief system. With the Turbo-Master, turbine inlet pressure is retained up to the preset point of bypass. This results in turbocharger performance that is increased across the design operational range. Even on an otherwise stock Cummins engine performance is increased by virtue of the resultant steady boost pressure.

To ensure the correct Turbo-Master is selected for your application, please confirm your turbocharger's wastegate design using the pictures below. Many customers have turbochargers installed on their trucks that may be different from the model that typically came with the truck from the factory. The year model truck you have does not always correspond with a specific turbocharger model.

Was:

$199.99

Sale:

$159.99

Save:

20%

Save:

$40.00

Description

A few words from the designer/ Patent holder:

The boost pressure controller used in many applications of Ford and Dodge, use a canister, which features a spring that applies a closing force on the turbocharger waste gate valve.

Included in the canister is a boost pressure-sensing diaphragm that applies a force, which counters that of the spring.

As boost pressure rises, an ever-increasing counter-force is affected against the spring, lessening the force applied to the waste gate valve, causing it to allow bypassing of turbine inlet pressure (drive pressure) to limit shaft speed and consequent boost pressure output.

The major drawback with this type control is that it begins to bleed-off turbine inlet pressure well in advance of the desired, boost pressure limit. In the typical application, the closing force on the waste gate is relaxed sufficiently to allow this bypassing at boost pressure outputs, which are approximately 1/2 of the target. In other words, set to 20 this starts to open at 10.

This 'wasting' of turbine inlet pressure, which occurs in the upper half of the boost pressure output curve, results in a relatively lazy turbocharger performance that affects the mid to upper range engine performance.

The Turbo-Master mechanical waste gate controller is designed to function as a 'turbine-inlet pressure' relief-valve mechanism. It will keep the waste gate valve closed, retaining turbine inlet pressure up to the predetermined, pressure bypass point. When turbine inlet pressure reaches that preset point, the waste gate valve is forced off its seat to allow bypassing of any excess turbine inlet pressure, thereby controlling shaft speed and boost output pressure.

The reason for the longer lever? The Turbo-Master design features a waste gate lever that is longer than the stock unit. This helps to overcome the friction inherent to the waste gate shaft / bushing, resulting in a smooth, predictable waste gate function.

The advantage of retaining all turbine inlet pressure up to the point of bypass is a full utilization of all available turbine inlet pressure. The turbocharger will provide a more efficient boost pressure output curve, with better engine performance in the upper half of that curve.

The boost pressure controller used in many applications of Ford and Dodge, use a canister, which features a spring that applies a closing force on the turbocharger waste gate valve.

Included in the canister is a boost pressure-sensing diaphragm that applies a force, which counters that of the spring.

As boost pressure rises, an ever-increasing counter-force is affected against the spring, lessening the force applied to the waste gate valve, causing it to allow bypassing of turbine inlet pressure (drive pressure) to limit shaft speed and consequent boost pressure output.

The major drawback with this type control is that it begins to bleed-off turbine inlet pressure well in advance of the desired, boost pressure limit. In the typical application, the closing force on the waste gate is relaxed sufficiently to allow this bypassing at boost pressure outputs, which are approximately 1/2 of the target. In other words, set to 20 this starts to open at 10.

This 'wasting' of turbine inlet pressure, which occurs in the upper half of the boost pressure output curve, results in a relatively lazy turbocharger performance that affects the mid to upper range engine performance.

The Turbo-Master mechanical waste gate controller is designed to function as a 'turbine-inlet pressure' relief-valve mechanism. It will keep the waste gate valve closed, retaining turbine inlet pressure up to the predetermined, pressure bypass point. When turbine inlet pressure reaches that preset point, the waste gate valve is forced off its seat to allow bypassing of any excess turbine inlet pressure, thereby controlling shaft speed and boost output pressure.

The reason for the longer lever? The Turbo-Master design features a waste gate lever that is longer than the stock unit. This helps to overcome the friction inherent to the waste gate shaft / bushing, resulting in a smooth, predictable waste gate function.

The advantage of retaining all turbine inlet pressure up to the point of bypass is a full utilization of all available turbine inlet pressure. The turbocharger will provide a more efficient boost pressure output curve, with better engine performance in the upper half of that curve.

Details

- TM24

- TM24

- DieselSite

- New

Categories

Shipping Information

- Item Requires Shipping

- 1.0 lbs.

- W7.0000” x H3.0000” x L9.0000”

- Free Shipping

Customer Reviews

Total Reviews (0)

Total Reviews (0)

You must login to post a review.

Write the First Review!